| In the Eye of the Cyclotron: Precision Lifting Systems Serving Proton Therapy Centers |

| With its worm gear screw-jack drives, Pfaff-silberblau is making a valuable contribution to successful radiation therapy for treating cancer. |

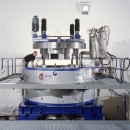

| Friedberg and Hannover, Germany, April 11, 2005 – Pfaff-silberblau Hebezeugfabrik GmbH & Co. KG of Friedberg/ Derching, Germany, is presenting one of its newest system solutions for medical applications at the Hanover Fair 2005: The “Acutator Technology” division has developed a precision lifting system commissioned by the company ACCEL Instruments of Bergisch Gladbach, Germany, for use in proton therapy centres for performing radiation therapy on cancer tumors. The system from Pfaff-silberblau – which is currently being used in centres in Southern Germany and in Switzerland – safely and precisely lifts the approximately 20-ton upper section of a device referred to as a “cyclotron” and thus makes adjustment and maintenance work possible to ensure ideal operating conditions for this therapy device. A decisive advantage lies in the fact that the system does not require any additional guides and that it complies with the requirements of EN 1570 (formerly VBG 14). A cyclotron is a circular particle accelerator that uses powerful magnetic fields to accelerate protons on a spiral path. This generates protons beams that move at a speed of 180,000 km/s (approx. 110,000 miles per second) – which corresponds to 60 percent of the speed of light. Once they have reached the end of their most outward path and have achieved their highest-possible final energy levels, these beams are deflected out of the cyclotron and transmitted to a therapy station via vacuum tubes. By aiming them precisely at the tumor cells, which can be localized precisely beforehand using computer tomography, the proton beams destroy the cells without damaging the surrounding healthy tissue. To make it possible to safely adjust and service the cyclotron’s complex construction, Pfaff-silberblau developed a precise drive system with worm gear screw jacks. This system lifts the heavy upper section (which weighs about 20 metric tons) of the circular particle accelerator with a precision of 0.1 mm over a lifting distance of 1,200 mm. Here, precision is critical, because there is only a gap of 0.3 mm when the upper section moves into the lower section. Any deviation of the lifting movement to the side would cause enormous damage and endanger the system’s ability to function and its availability for use. This difficult challenge is accomplished using four size 25 screw jacks with reinforced, self-locking spindles made of ground, semi-finished material. Here mitre gear boxes are used to connect the screw jacks via high flexible shafts to form a mechanically coupled unit. For their design, the drive specialists from Pfaff-silberblau exclusively used modified elements from the company’s proven module system and thus created a lifting system that is not only precise, but also economical. The self-locking spindles that are used have a small lead angle as well as an actuator motor with a brake, so there is double protection against unintentional displacement during the operating phase or when performing work apart from the use of the lifting drives. Furthermore, the worm gear screw jacks are equipped with additional safety nuts that electrically monitor breakage of the thread on the main nut. This is an integral part of the EN directives and it reliably prevents harm to personnel or damage to material should the main nut break at any time during the system’s service life. Overall, the design requirements for proton therapy systems might seem relatively high compared to the requirements for conventional radiation therapy. Nevertheless, the success proves that this method is worth the effort: With proton therapy, post treatment is hardly necessary. In 95 percent of the cases treated, it was possible to stop the tumor’s growth, and the probability of recovery is approximately 30 percent higher, even in difficult cases. |

| About Pfaff-silberblau Pfaff-silberblau Hebezeugfabrik & Co. – which was established over 135 years ago – currently has 360 employees and a group turnover in excess of 62 million euros (2004 fiscal year). The company is a leader in the fields of hoisting machinery and materials handling equipment, actuator technology/ worm-gear screw jacks, stage technology, road & rail, and materials handling technology. Pfaff-silberblau is an experienced partner for solving any problem related to moving (turning, lifting, lowering, pushing, shunting) loads of up to 1,000 tons in any direction. The company has factories in Friedberg and Heilbronn (Germany), and is represented by its own national companies in Switzerland as well as Austria, England, the Benelux countries, Poland and Hungary. Beyond that, more than 40 affiliated representative offices are active for Pfaff-silberblau around the world. |

| Press Releases online: | 4639 |

| Press Releases | | | Newsletter | | | Search | | | Agency | | | German |