| ROHMís New TRCDRIVE packô with 2-in-1 SiC Molded Module: Significantly Reduces the Size of xEV Inverters |

| Achieves industry-leading* power density by integrating 4th Generation SiC MOSFETs in a compact package |

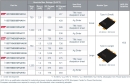

| Willich-Münchheide, Germany, June 11, 2024 Ė ROHM has developed four models as part of the TRCDRIVE pack™ series with 2-in-1 SiC molded modules (two of 750V-rated: BSTxxxD08P4A1x4, two of 1,200V-rated: BSTxxxD12P4A1x1) optimized for xEV (electric vehicles) traction inverters. TRCDRIVE pack™ supports up to 300kW and features high power density and a unique terminal configuration - help solving the key challenges of traction inverters in terms of miniaturization, higher efficiency, and fewer person-hours. (Fig. 1) As the electrification of cars rapidly advances towards achieving a decarbonized society, the development of electric powertrain systems that are more efficient, compact, and lightweight is currently progressing. However, for SiC power devices that are attracting attention as key components, achieving low loss in a small size has been a difficult challenge. ROHM solves these issues inside powertrains with its TRCDRIVE pack™. A trademark brand for ROHM SiC molded type modules developed specifically for traction inverter drive applications, TRCDRIVE pack™ reduces size by utilizing a unique structure that maximizes heat dissipation area. On top, ROHMís 4th Generation SiC MOSFETs with low ON resistance are built in - resulting in an industry-leading power density 1.5 times higher than that of general SiC molded modules while greatly contributing to the miniaturization of inverters for xEVs. The modules are also equipped with control signal terminals using press fit pins enabling easy connection by simply pushing the gate driver board from the top, reducing installation time considerably. In addition, low inductance (5.7nH) is achieved by maximizing the current path and utilizing a two-layer bus-bar structure for the main wiring, contributing to lower losses during switching. (Fig. 2) Despite developing modules, ROHM has established a mass production system similar to discrete products, making it possible to increase production capacity by 30 times compared to conventional SiC case-type modules. Product Lineup TRCDRIVE pack™ is scheduled to be launched by March 2025 with a lineup of 12 models in different package sizes (Small / Large) and mounting patterns (TIM: heat dissipation sheet / Ag sinter). In addition, ROHM is developing a 6-in-1 product with built-in heat sink that is expected to facilitate rapid traction inverter design and model rollout tailored to variety of design specifications. (Fig. 3) Application Examples Automotive traction inverters Sales Information Availability: June 2024 (OEM quantities) Comprehensive Support ROHM is committed to providing application-level support, including the use of in-house motor testing equipment. A variety of supporting materials are also offered, such as simulations and thermal designs that enable quick evaluation and adoption of TRCDRIVE pack™ products. Two evaluation kits are available as well, one for double-pulse testing and the other for 3-phase full bridge applications, enabling evaluation in similar conditions as practical inverter circuits. For details, please contact a sales representative or visit the contact page on ROHMís website. (Fig. 4) EcoSiC™ Brand EcoSiC™ is a brand of devices that utilize silicon carbide (SiC), which is attracting attention in the power device field for performance that surpasses silicon (Si). ROHM independently develops technologies essential for the evolution of SiC, from wafer fabrication and production processes to packaging, and quality control methods. At the same time, we have established an integrated production system throughout the manufacturing process, solidifying our position as a leading SiC supplier. TRCDRIVE pack™ and EcoSiC™ are trademarks or registered trademarks of ROHM Co., Ltd. *ROHM June 11, 2024 study |

| About ROHM Semiconductor ROHM Semiconductor is a global company of 467.7 billion yen (3.2 billion US dollars) per March 31st, 2024, with over 23,300 employees. The company develops and manufactures a very large product range from SiC Diodes and MOSFETs, Analog ICs such as Gate Drivers and Power Management ICs to Power Transistors and Diodes to Passive Components. The production of ROHMís high performing products is taking place in state-of-the-art manufacturing plants in Japan, Germany, Korea, Malaysia, Thailand, the Philippines, and China. ROHM Semiconductor Europe has its Head Office near Dusseldorf serving the EMEA region (Europe, Middle East, and Africa). For further information: www.rohm.com |

| Press Releases online: | 4639 |

| Press Releases | | | Newsletter | | | Search | | | Agency | | | German |